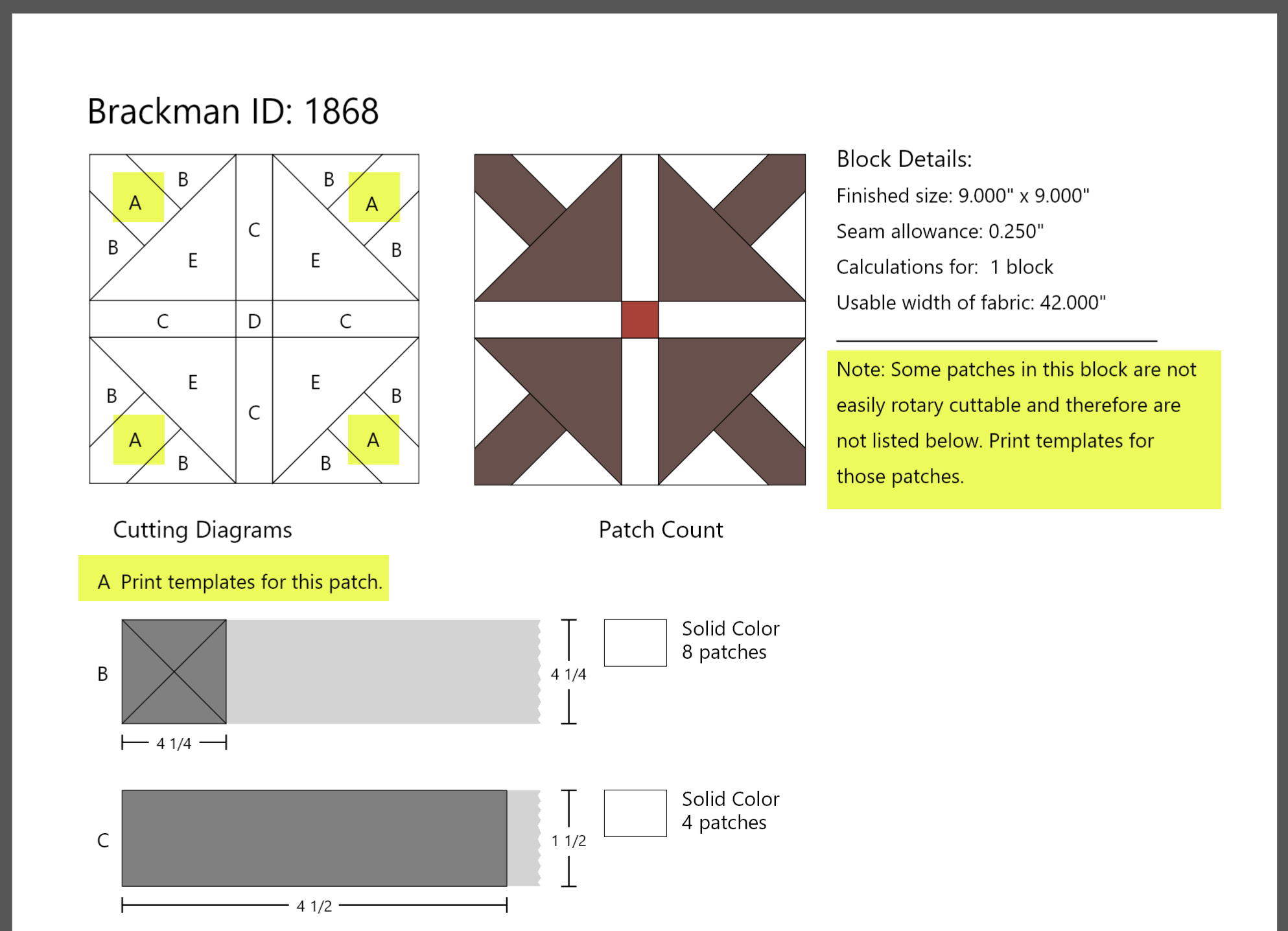

Not All Patches are Rotary Cuttable

BlockBase+ does not give results for all shapes. Kite shapes are one example. These shapes will be lettered in the Key Block and in the chart it will tell you to “Print templates for this patch.” Depending on the number of patches that may be missing, selecting a different pattern type, like templates or foundation patterns, may be a better alternative.

Rounding is Required

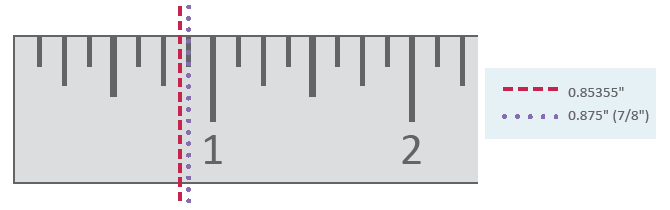

Rotary cutting dimensions are nearly always approximations. For example, the 7/8 inch that quilters conventionally add for half-square triangles is really .85355 inches, rounded off to the nearest 1/8 inch so that we can read it on the ruler. Experienced quilters in fact cut a little “shy” in this case, since .85355 is a little less than 7/8.

This applies, of course, to the dimensions given in BlockBase+ rotary cutting printouts. Because of this, the rotary cutting instructions may not always be the best guide to cutting your block. Here are some things that you should know when deciding on the best type of pattern to use for a given block.

BlockBase+ Gives the Conventional Results

In simple cases, rectangles and triangles in even sizes, for example, BlockBase+ gives the same results as conventional quilter’s wisdom. It adds 1 1/4 inch to the finished size of quarter-square triangles, for example, just like the books.

But, BlockBase+ gives rotary cutting dimensions even in cases where the conventional rules of thumb do not apply. Here you need to be aware that rounding off to the nearest 1/8 or 1/16 inch may produce inaccuracies. The following example illustrates the point very well.

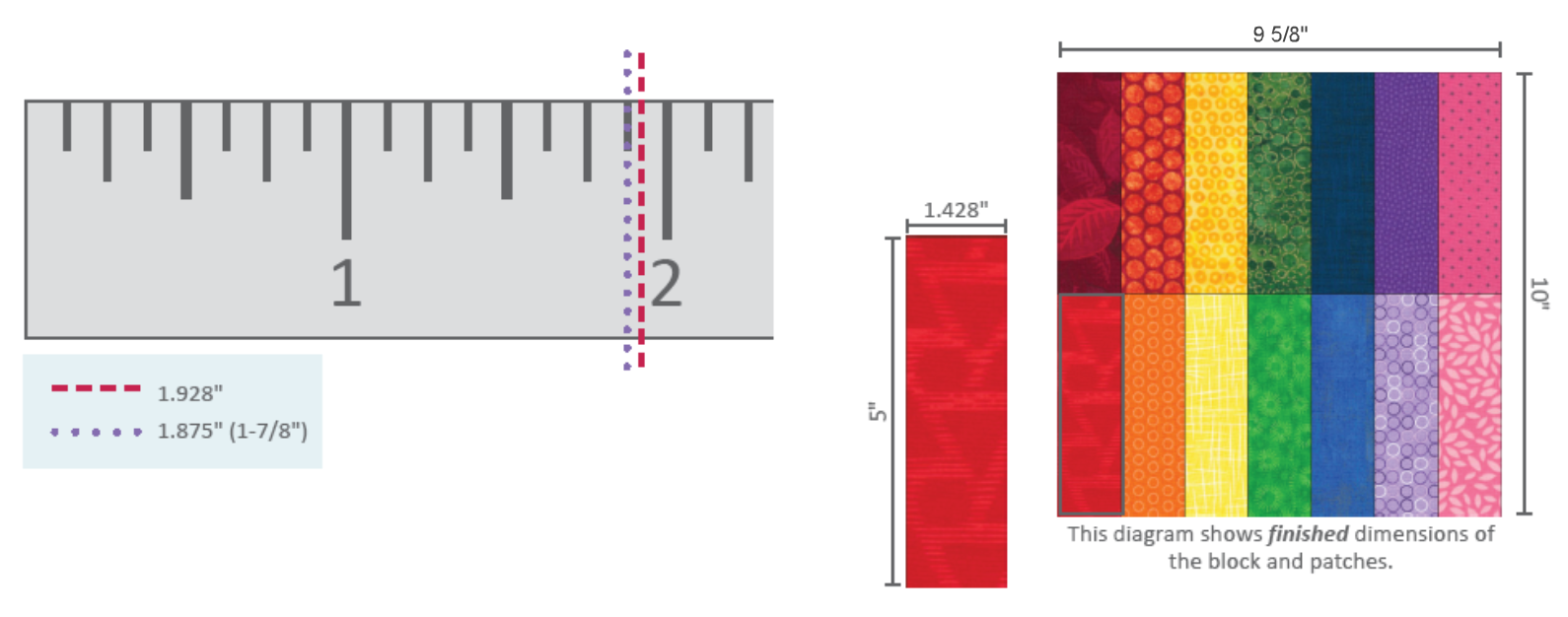

The inaccuracies produced by rounding off can become significant if the finished sizes of patches are not easily measured on common rulers. This block has 7 patches across by five patches down. If you wanted a 10 inch block, this would mean that each rectangle has a finished size 1.43″ by 2″. 1.43 is not to be found on your ruler.

BlockBase+ would add the 1/4 inch seam allowance, round off (say, to the nearest 1/8 inch), and tell you to cut rectangles 1 7/8″ by 2 1/2″. If you then pieced together these pieces (assuming you use accurate quarter inch seams), the finished size of the actual block would come out to be 9 5/8″ by 10, a full 3/8 inch too narrow!

Templates May Be Used as a Check

BlockBase+ templates are always accurate. If you are uncertain about rotary cutting dimensions in some cases, print the templates as a check. The actual (unrounded) dimensions for rotary cutting may be measured from the dotted (seam allowance) lines on the templates. First extend the dotted lines until they cross. Then measure the resulting total length and height.

Block Design Impacts Block Size

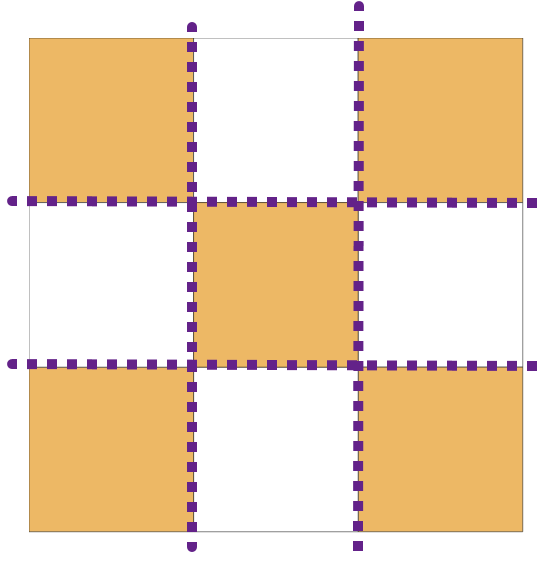

Visualize a grid of squares over the design of the block to help you determine the best size to make a block. For example, a Nine Patch style block works well at 3, 6, 9, 12 and so on for the overall size.

In the sample block with 7 across, 10 inches is not a good size choice. If we choose 10.5 inches for the size of the block and turned off all rounding, the Rotary Cutting Chart tells us to cut the strips 2.0″ by 5.75″. When we turn on rounding, we get the same sizes! So by changing the overall block size, we’ve eliminated all the rounding.

BlockBase+

BlockBase+